|

TOPLEA MACHINERY IMP &.EXP CO.,LTD

|

waste gas treatment Condenser

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Exhaust gas treatment system

2.Condenser cool the waste gas to water

3.Residual gas emissions by spray

4. Save water resource and Eco-friendly

Company Introduction

Our co-operate company, awarded "China Drying Equipment Industry Excellent Enterprise", has gathered more than 20 years in the field of waste treatment and management and has gradually developed into an integrated enterprise with research & development, manufacture, installation & debugging, specialized in manufacturing rendering equipment for processing waste from slaughtering for poultry, livestock, fish and so on. Rendering Equipment focuses on help our customers treat with slaughterhouse waste eco-friendly and gain the increased profit from the finished product such as feather meal, meat and bone meal, blood meal, fish meal and so on .

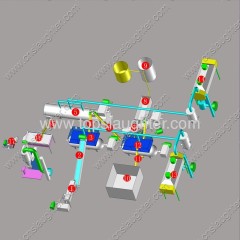

Equipment components:

1. Catcher 2. Condenser 3. Water Ring Vacuum Pump SK-6 4. Exhaust steam tank

Process Description:

High pressure and temperature curing tank exhaust emissions generated by the water-ring vacuum pump vacuum drainage from the exhaust port into the set to catch, and then into the condenser for cooling. The exhaust gas condenses into water to collect emissions, a small amount of residual gas emissions into the exhaust chimney, high temperature combustion to achieve zero emissions standard.

Technical Parameters:

Specification:1000X1000X4500mm

Outer case of main body use SUS304, δ=6mm

Catcher Φ600X1500, all made of SUS304, stainless steel δ=3mm

Cooling pipe Φ32×2.0 use SUS304

SK-6 water ring vacuum pump Power P=11kw; SUS304 stainless steel

Pipeline pump power=5.5kw;

Waste water storage tank Φ800X2000, casing made of Q235B carbon steel, δ=6m

Process Principle

Waste gas treatment system uses vacuum drying and cooling device to cool down the waste gas into waste water, which is to save water resources. The residual gas will be processed by condensation method. Then the rest of the gas will reach emission standard though spraying.

Waste gas treatment; Condenser