|

TOPLEA MACHINERY IMP &.EXP CO.,LTD

|

Rendering Equipment High Temperature Hydrolysis Tank

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

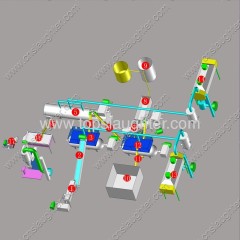

1.Rendering Equipment Hydrolyser for slaughterhouse waste (feather, offal)

2.Curing, aging, sterilization

3.Feather powder, meat bone powder

4.37 k

Hydrolyzer Unit

Working Principle: Use main shaft and outer jacket filled with steam to enhance the heat change area, so that to add pressure to the tank. The raw material will be processed by high temperature hydrolysis with uniformly stirred by blades synchronously to make the raw material in powder form and reach the aging and sterilization effect.

Feature: use silo conveying to make the hydrolysers combined together, which will improve curing efficiency.

Technique Parameter

Specification :5600X1600X2200mm

Motor Power: P=37kw

●Main shaft use Φ325×22 seamless steel pipe, Q235B carbon steel, filled with steam to enhance heat exchange area. | ●Stirring blades distributed evenly in the tank, made of wear-resisting material Q345R, thickness δ=16mm |

●Inner cylinder use 16MnR Pressure Vessel Plate, thickness δinner=16mm;Outer Jacket use 16MnR Pressure; Vessel Plate thickness δ outer=12mm;Flange thickness δ=40mm,seal head δ=16mm; | ●Draining device: equipped with rotating joints and stainless steel hose DN50 to discharge condensation water from main shaft and jacket |

●Jacketed structure, spacing between inner and outer<=60mm;< div=""> | ●Insulation: use aluminum silicate, protection plate made of stainless steel SUS304, thickness δ=0.7mm |

●one outlet | ●Reducer: hard tooth surface:ZSY280 |

●Steam: working pressure 0.7MPa (164℃) | ●Air consumption: 700kg/h; |

●Bearing:double row self-aligning Bearing 3526, thrust bearing 8326; |

Rendering Equipment Hydrolyser for curing and sterilizing slaughterhouse waste ( feather, offal, blood, bone etc.)