|

TOPLEA MACHINERY IMP &.EXP CO.,LTD

|

Rendering Plant Hydrolyzing Tank for Poultry Slaughterhouse Waste

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Latest hydrolyzer tank used in the rendering plants

2.For feather, offal, bone, residue

3 High-temp and high pressure

4.Eco-friendly,Value added

New Type

Product Application

Applied for slaughter house waste, such as poultry feather, offal, furry animal's bone, viscera , intestine, waste residue, and the dead carcass of poultry and livestock in the transit. The finished product can be feather meal, meat and bone meal, blood meal, feather and offal meal.

Equipment Parameter

Tank Dimension (mm) | Effective Volume (m3) | Output (ton/ batch) | δInner mm | Power (kw) | Driving Mode | Reducer | n/min |

Φ1300×3600 | 3.3 | 1.3 | 14 | 22 | Chain | ZQ650 | 20 |

Φ1400×3800 | 4.3 | 1.6 | 16 | 30 | Chain | ZQ650 | 20 |

Φ1500×4000 | 5 | 1.8 | 18 | 22 | Gear | ZQ650 | 16 |

Φ1600×4500 | 6.4 | 2.0 | 20 | 30 | Gear | ZQ650 | 14 |

Φ1800×5000 | 9 | 2.8 | 20 | 30 | Gear | ZQ650 | 12 |

Φ2000×5000 | 10.9 | 3.5 | 37 | 37 | Gear | ZQ750 | 8 |

Performance Characteristic

Our new type updated hydrolysis feather powder equipment, based on the advanced technology and combined with our more than 20 years' manufacturing experience. It adopts high temperature, high pressure, and strong shear force, the outstanding feature of which is to completely destroy feather keratin structure, to turn food industry waste into fully digestive soluble protein, realizing value added and increased profit.The average digestibility and absorption rate reach more than75%, tested by authority.

Updated Technology As Follows:

1.In order to meet the hydrolyzing requirement of rapid heating, the heat transfer area increased about 40% compared with the previous same model.

2.Similarly, heat-transfer capability of unit area added means to improve heat transfer coefficient k, to turn K value to be 75kcal/m2°Ch from

from 50-6 kcal/m2°Ch. Heating surface self-cleaning adopted, the equidistant of heating surface from center material to the around, heating surface evenly distributed in the tank

3. In order to improve anti-pressure capacity, weak link has been improved in the new type to eliminate or reduce most area of stress concentration, load condition of bearing components improved. The main pressure parts use 20g, 16mnR, 20c and other high quality boiler pressure vessel steel, to improve equipment safety and applicability. Several measures are taken as follows:

(1). Increasing the number of stirring blades. (2). Changing the shape of the stirring blades.(3). Increasing the relative speed by interphase structure between fixed gear and moving gear, quality and production efficiency have been raised through those measures.

a.Cystine content and digestibility improve significantly. Amino acid digestibility reach 41-80%, and also pepsin digestibility (PDP), amino acid) efficiency (PDAA), soluble protein (PS), amino acid content, bulk density (BD) and other index improve significantly.

b. Operating time shortened, high steam efficiency and high heat efficiency, about 6% steam saved based on the actual measurement

b. Stable quality, because of rapid, evenly, uniform and stable heating

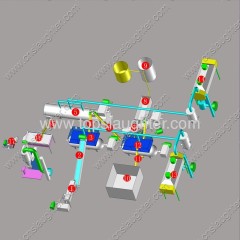

Product Picture