|

TOPLEA MACHINERY IMP &.EXP CO.,LTD

|

Meat processing equipment steam boiler

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

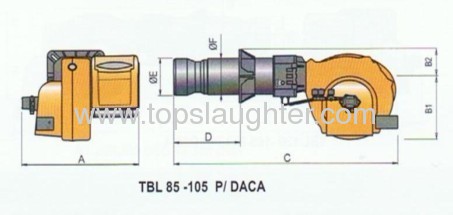

1.Boilers Bunner TBL 85-105/DACA TBL130-160-210P BT 75-105-120 DSPG BT180DSP

2. Automatic, environmentally friendly, safety, high efficiency, stable

Burner is the most important equipment in the boiler. We recommend you Italian famous brand BALTUR, which enjoys a good reputation and occupies a large market share.

Product Features

Automatic Control:

a. When the pressure is too high, the water level is too low, the burner stops burning;

b. The burner itself has automatic ignition, blowing burning and other process control system. When one process failed to meet its normal condition, burner will automatically interrupt work;

c. When the temperature sensor detects a temperature above (below) the set value, the burner will stop (start) combustion;

d. With electric eye sensor security system.The heating system with a very high thermal efficiency, fewer start up time, low energy consumption, good energy-saving effect.

Fewer startup time.

Full combustion, little environmental pollution, environmentally friendly.

Superior performance, smooth running, low noise, with a good noise elimination function.

Unique backflow device can recycle remaining oil through circulating piping or tank.

Air consumption adjusted automatically by burner nozzle, to match jet volume with boiler loading capacity (steam supply) and ensure full combustion.

Start and stop quickly, fast steam supplying.

Technical Parameters

TBL 85-105/DACA TBL 130-160-210P

1. Two-stage working (big/small fire);

2. Mechanical pressure atomization;

3. Burner emission reaching Reach EU Standards CLASSIII;

4. Double hinge connection;

5. Easily maintained and adjustable without detaching burner down;

6. Lightweight aluminum alloy die-casting electric control box, suitable for 4 and 7 hole plug connection;

7. Electric control box protection degree: IP55;

8. Equipped with two hose, one in-line filter, two nozzles, one plug of four holes and one plug of seven holes

9. Electric motor reaching EU Standards:IE2;

10. Silencer design;

11. Hydraulic regulator controlling damper to adjust airflow volume of 1 and 2 stage working; damp controlled by servo motors

12.Gear pumps with voltage regulator, pressure taps and relief valve;

13. Flame detection by photoconductive resistance;

14. Electrical connected BY printed circuit boards, including big or small button to connect power and thermostat with 7 hole plug, and two stage flame control stage of four hole thermostat.

Burner

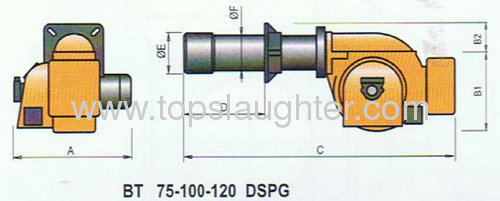

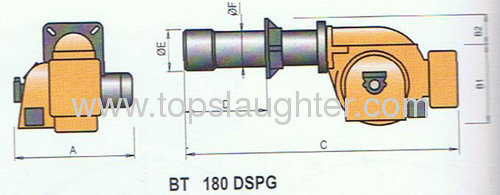

BT 75-105-120 DSPG BT180DSPG

1.Two stage flame progressive operating;

2. Equipped with cTRON 08regulator, operating by ratio control;

3. Atomizing device (electromagnetism controlling nozzle adjusting rod);

4. Servo motor adjusts damper;

5. Equipped with two hose, two in line fitter (not including nozzle, need to order separately);

6. Electric motor reaching EU Standards: IE2;

7. Mechanical pressure atomization;

8. Combustion air with flow adjustment regulator;

9. Service motor with cam to adjust supply of air and fuel;

10. Gear pump with voltage regulator;

11. Flame detection by Photoconductive resistance;

12. Standard Electrical protection grade I40 ( for other requirement can raise the protection)

TBL 85-105/DACA BT 75-105-120 DSPG

| TBl-BT burner 200~`1660KW/0.7-1.2T TBL 85-105/DACA BT 75-105-120 DSPG | ||||||||||||

| Model | A(mm) | B1(mm) | B2(mm) | C(mm) | D(mm) | E(mm) | F(mm) | I(mm) | I1(mm) | L(mm) | M(mm) | N(mm) |

| TBL85 P | 670 | 380 | 130 | 1245 | 175~400 | 161 | 159 | 260 | 260 | 225~300 | M12 | 170 |

| TBL85 P DACA | 670 | 380 | 130 | 1245 | 175~400 | 161 | 159 | 260 | 260 | 225~300 | M12 | 170 |

| BT 75 DSPG | 595 | 365 | 150 | 1215 | 130~450 | 205 | 160 | 260 | 260 | 255~300 | M12 | 170 |

| BT 100 DSPG | 685 | 365 | 160 | 1415 | 310~490 | 230 | 195 | 320 | 276 | M16 | 240 | |

| TBL 105 P | 680 | 380 | 140 | 1245 | 175~400 | 180 | 178 | 280 | 280 | 250~325 | M12 | 190 |

| TBL 105 P DACA | 680 | 380 | 140 | 1245 | 175~400 | 180 | 178 | 280 | 280 | 250~325 | M12 | 190 |

| BT 120 DSPG | 770 | 470 | 160 | 1415 | 155~500 | 230 | 195 | 320 | 276 | M16 | 240 | |

| TBL-BT Burner 200~`1660KW/0.7-1.2T TBL 85-105/DACA BT 75-105-120 DSPG | ||||||||

| Model | No. | Power | Light oil flow | Max viscosity | Power Supply | Motor power | Size | Weight |

| KW | KG/H | KW | LxPxH mm | kg | ||||

| TBL 85 P | 35800010 | 200~850 | 16.9~71.6 | 1.5 | 3N AC 50HZ 400V | 1.1 | 1070x800x700 | 79 |

| TBL 85 P DACA | 35800110 | 200~850 | 16.9~71.6 | 1.5 | 3N AC 50HZ 400V | 1.1 | 1070x800x700 | 79 |

| BT 75 DSPG | 3510010 | 475~889 | 35~75 | 1.5 | 3N AC 50HZ 400V | 1.1 | 1730x1030x880 | 140 |

| BT 100 DSPG | 3514010 | 533~1186 | 45~100 | 1.5 | 3N AC 50HZ 400V | 1.5 | 1730x1030x880 | 150 |

| TBL 105 P | 35850010 | 320~1050 | 27~88.5 | 1.5 | 3N AC 50HZ 400V | 1.5 | 1070x800x700 | 80 |

| TBL 105 P DACA | 35850110 | 320~1050 | 27~88.5 | 1.5 | 3N AC 50HZ 400V | 1.5 | 1070x800x700 | 80 |

| BT 120 DSPG | 3518010 | 474~1660 | 40~140 | 1.5 | 3N AC 50HZ 400V | 2.2 | 1730x1030x880 | 175 |

TBL 130-160-210P BT180DSPG

| TBL 130-160-210P BT180DSPG 400~`2135KW/1.3-2.5T | ||||||||||||

| Model | A(mm) | B1(mm) | B2(mm) | C(mm) | D(mm) | E(mm) | F(mm) | I(mm) | I1(mm) | L(mm) | M(mm) | N(mm) |

| TBL130 P | 680 | 380 | 140 | 1250 | 175~400 | 180 | 178 | 280 | 280 | 250~325 | M12 | 190 |

| TBL130 P DACA | 680 | 380 | 140 | 1250 | 175~400 | 180 | 178 | 280 | 280 | 250~325 | M12 | 235 |

| TBL 160 P | 680 | 365 | 140 | 1300 | 200~450 | 224 | 219 | 320 | 320 | 280~370 | M12 | 235 |

| TBL 160 P DSPG | 680 | 380 | 160 | 1300 | 200~450 | 224 | 219 | 320 | 320 | 280~370 | M16 | 235 |

| BT 180 DSPG | 930 | 580 | 200 | 1700 | 210~650 | 260 | 220 | 320 | 320 | 280~370 | M12 | 230 |

| TBL 210 P | 680 | 380 | 160 | 1300 | 210~450 | 250 | 219 | 320 | 320 | 280~370 | M12 | 235 |

| TBL 130-160-210P BT180DSPG 400~`2135KW/1.3-2.5T | ||||||||

| Model | NO. | Power | Light oil flow | Max viscosity | Power Supply | Motor Power | Size | Weight |

| KW | KG/H | KW | LxPxH mm | kg | ||||

| TBL 130 P | 35900010 | 400~1300 | 33.7~109.6 | 1.5 | 3N AC 50HZ 400V | 2.2 | 1070x800x700 | 85 |

| TBL 130 P DACA | 35900110 | 400~1300 | 33.7~109.6 | 1.5 | 3N AC 50HZ 400V | 2.2 | 1070x800x700 | 85 |

| TBL 160 P | 35950010 | 500~1600 | 42.2~134.9 | 1.5 | 3N AC 50HZ 400V | 2.2 | 1070x800x700 | 90 |

| TBL 160 P DACA | 35950110 | 500~1600 | 42.2~134.9 | 1.5 | 3N AC 50HZ 400V | 2.2 | 1070x800x700 | 90 |

| BT 180 DSPG | 3522010 | 712~2135 | 60~180 | 1.5 | 3N AC 50HZ 400V | 3 | 1730x1030x880 | 220 |

| TBL 210 P | 36000010 | 800~2100 | 67.5~177 | 1.5 | 3N AC 50HZ 400V | 3 | 1070x800x700 | 90 |