|

TOPLEA MACHINERY IMP &.EXP CO.,LTD

|

Food Processing Machine Slaughterhouse Equipment

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.TOPEA professional poultry processing equipment company

2.More than 35 years' experience

3.First chiller machine made by us

4.Plucking rate:≥99%

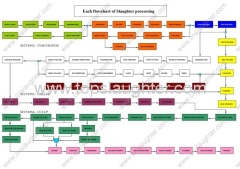

Process Design for Poultry Processing Plants Live Poultry Area (III)

Technology and Equipments of Live Birds Area

1. Live Poultry Receiving

Special passage should be set for live poultry vehicles. At the entrance of the plant, there needs to set a disinfection pool (3m long and 100-150 deep), the same wide as the entrance door, to disinfect for wheels.

Parking area with shed from, at the top or the side with fan or spray cooling system, cold prevention facilities needed in the cold region.

Try not to weight at the live birds area, to use advanced poultry processing carcass interval weighing system, to improve management level.

2. Unloading

It can greatly reduce the labor intensity that crates conveyor and unloading platform are set in the same working height. Two workers carry the crates from the vehicle, each stack with 8-9 layers, unloading 12000 birds finished per hour.

Normally, unloading platform required storing more crates. WSPA (world society for the protection of animals) rules after live birds reaching poultry slaughterhouse, they will be killed within 1h, not more than 2h. Take a poultry processing plant with 12000 bph line as example, parking place should be designed for 5 trucks, unloading area suitable for 2 trucks and need to be set spare crates storage room.

3. Crates Distribution

Try to use automated crates unloading and distributing, high efficiency and low labor intensity. Interact effect need to be considered when designing.

Meat Processing Industry Slaughtering Equipment

Meat Processing Industry Poultry Abattoir Equipment

Food Processing Machinery Slaughter Machine

Farm Machinery Chicken Slaughter Machine