|

TOPLEA MACHINERY IMP &.EXP CO.,LTD

|

Poultry Processing Equipment Live Birds Reception Area

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Live birds area at the downwind area of poultry processing plant

2.Single layer is suitable ,net height not less than 4.2m

3.Pillar space ≥6m

Technology Design for Poultry Processing Plant Live Birds Area (I)

I. Working Area Definition

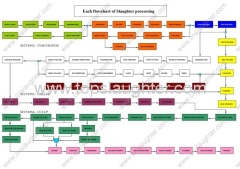

Although there is no clear scope and definition for the front part working area of the poultry processing plant, those area must meet the animal Animal welfare requirements. It is widely accepted that after bleeding process finishes, it indicates that poultry have died. Therefore, the following processes, hanging, stunning, killing, bloodletting, should be considered as one working area. Thus, we define it as "live bird area", which means the working area ,after birds reception and before bleeding finish.

II. Layout of Live Poultry Area and Main Facility

1. According to the regulation, live birds area should be located at the downwind area of the poultry processing area. We can subdivide it as: parking area, waiting area, unloading area, live birds hanging area, stunning, killing and bleeding area, crates cleaning area, vehicles disinfection area, waste storage area, reception area and urgent killing room and so on.

2. For workshop of slaughterhouse, single layer is best. Net height should be not less than 4.2 meter; the pole space not less than 6 meter. Hanging area is the main working area, where hanging room should be designed to be darkroom , separately with other working areas.

3. Reception area set lose to one side of waiting-slaughtering area, including clearing room, official quarantine room and rest room for Iman, if there is halal processing products.

4. Auxiliary facility should be at the downwind area of live chicken area, that is harmless treatment plant, waste storage and treatment plant, waste water processing station, steam boiler room, coal yard. Live poultry area should avoid to harmful gas, smoke, dust and other pollution sources, including other polluting enterprises.