|

TOPLEA MACHINERY IMP &.EXP CO.,LTD

|

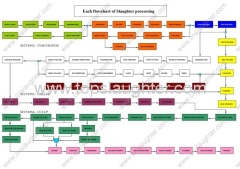

Chicken Processing Plants Food Processing Equipment

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Live bird area ,key to poultry processing plants

2.Ground drainage slope of unloading and hanging area ≥1%

3.Illumination for hanging area: 50lux

Technology Design for Poultry Processing Plants Live Poultry Area (II)

1. Occupation Area

Confirm the occupation area according to the processing capacity. Generally, for poultry single line, each chicken is 0.2-0.25m2, and for duck and goose, adding 15%.

2. Basic Requirements

a. Water Supply and Drainage

Water consumption in the live birds area accounts for 6.5% of the plant. Water production for each chicken is 0.015-0.025m3, for each duck is 0.02-0.03m3. Basically per ton of raw meat should not be more than 5.8m3. Except for crate washing and disinfection, water can be used recycled, whose quality should meet the GB/T18920 requirement.

b. Ground Slope

Water drainage slope of unloading and hanging area should be not less than 1%. Surface drainage slope of bleeding room not less than 2%, and its flow direction should meet the relative regulation and requirement.

c. Illumination in different process position

Unloading area 5lx, Quarantine 750lx, Live Birds Hanging Area 50lux (blue light), Slaughtering Room below 30lx, Passage 220lx, Others 540lx

3. Animal Warefare

When establishing HACCP, SSOP and other management system, our clients should consider details about "live birds area" first and make it compliant with relative regulation and requirements. Waiting-killing area should be equipped with cooling and insulation system and its surrounding should have shading facility to keep the poultry quiet. WSPA requirement: waiting time is 1h ,at most 2h, to ensure birds not react to produce stress reaction. " Live poultry area" is rather important area, which is one of the keys to influence the whole plant efficiency and product quality.

4. Requirements for Before and After Slaughtering

a. Stop feeding and water supplying before slaughtering

For large poultry processing plants, the processing capacity reaches 120000 per day. Facing such a big quantity, it is necessary to consider the problem about food and water stopping before birds killing, in order to decrease the poultry droppings in transit, to reduce disease spreading rate, to be easily for crate cleaning and reduce the cross contamination from the broken offal during the production. In China, most chicken processing plants adopt the following standard, feeding stop for 12h and water supplying stop for 1h.

b. Requirements of inspection and quarantine

Inspection before slaughtering and after slaughtering, should confirm to related regulation and requirement.

5. Electrical Safety

Electricity distribution grounding form TN-S, TN-C-S system, mesh shell of electrical equipment should be reliable grounding. Setting special electrical room, or ventilating drying place, IP55 protection grade. Emergency Stop Switch should be set in the staff working area.

6. Crates Specification

At present, there are two forms of applicable poultry crates, square type and ingot type. Square type: 1)750*550*270 mm 2) 800*600*300 mm. Ingot Type 760*550 *310 mm

7. Equipment Maintenance Passage

In the live poultry area, there should set equipment channel, which is easy for equipment handling when installing and repairing equipment, or significant process modification.