|

TOPLEA MACHINERY IMP &.EXP CO.,LTD

|

Meat Processing Industry Chicken Slaughter Equipment

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Toplea, as top quality packing solution supplier

2. Complete project with poultry processing project, rendering plant system and cold storage room

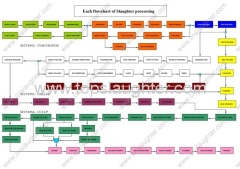

Process Design for Poultry Processing Plants Live Poultry Area (IV)

1. Hanging

a. High Suspension Line in the Live Birds Hanging area.

There should be set darkroom from birds hanging to stunning. The orbit of the overhead conveyor line should be kept in horizontal and straight form. Try to reduce the times of turns and up and-down movement; The high suspension line should adopt synchronous control technology and emergency stop system, to ensure the production line running reliable and stable. It is necessary to use appropriate shackles, according to different kinds of poultry and different breeding periods. Smooth appease board used to keep poultry quiet and ensure the chicken meat quality.

b. The Height Between Shackle Bottom and Ground

It is to ensure the height from the shackle bottom to the ground, according to the poultry breeds and Person's height in the north and south area. Normally, 1350-1400mm, for chicken about 1350mm, for duck about 1400mm.

c. The Working Height of Birds Hanging Conveyor

In order to prevent chicken heads hitting crates, the distance between shackle bottom and the top of the cage not less than 460mm, from the top of the crates to the ground not more than 900mm. The height of crate calculated as 300mm, so the conveyor machine's working height not more than 600mm. Considering the ground slope, there is adjustment range of 50mm. For duck, goose and other large poultry, the conveyor height should be lower appropriately.

2. Spacing and Quantity of Birds Hanging Work Station

The time for whole hanging action is 3.5s, that is, 1.5s for catching poultry from the crate, 0.5s for finding shackle position and wating, 1s for hanging and 0.5s for toching .With the production increases, the hanging movement become not continuous, movement range become bigger and bigger , operating spacing becomes wider and wider and auxiliary time becomes longer and longer. For poultry processing capacity, below 6000 bph, it belongs to small and medium-sized processing line, where line speed not more than 16m/min and operators can finish the action cycle, from birds catching to the hanging, without adding working station separately. However, if the production capacity is more than 8000 bph line, it needs to add working station for rehanging and poultry inspection, cause the chicken quantity are uneven in each crate and there always appears condition of empty cages.